Gripper Specifications

General Dimensions

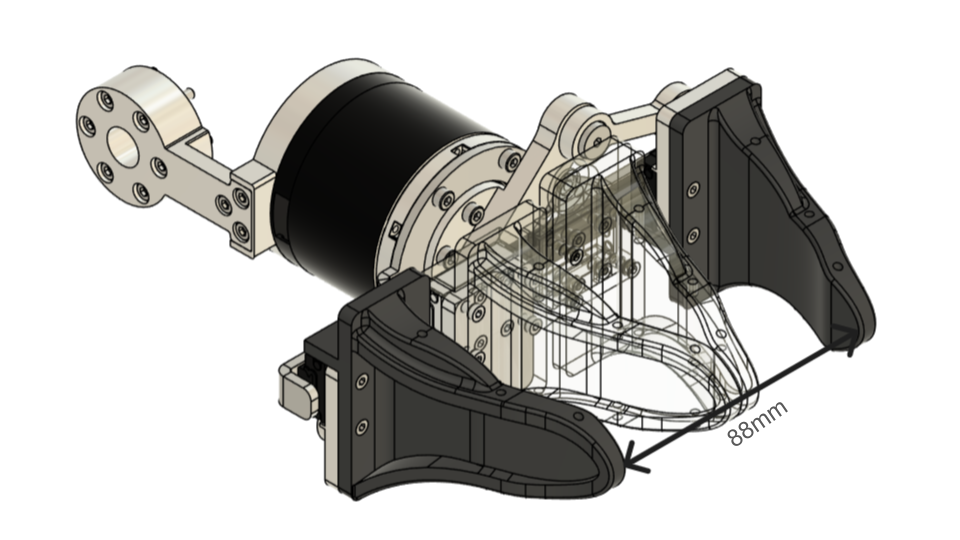

Maximum distance between the jaws is 88mm. Maximum closing is when the two jaws are in contact.

Mechanism

The rotor rotates 60° from the fully closed to fully open position. The motor's zero position is defined as when the gripper is fully closed. Ball-bearing slider blocks and rails, combined with bearings at the linkages, ensure exceptionally smooth motion—ideal for force feedback and bilateral control.

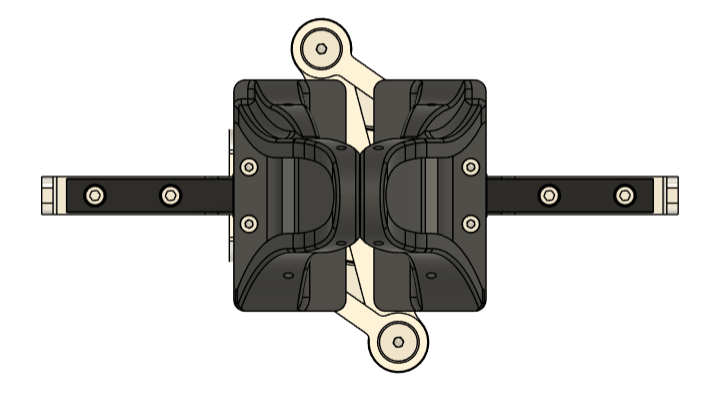

Gripper in fully closed position

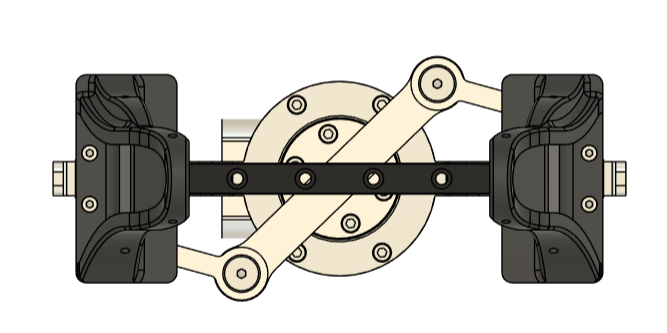

Gripper in fully open position (60° clockwise rotation from closed)

Using your own End-Effector

OpenArm design is flexible and allows you to easily attach your own custom end-effector (e.g., grippers, cameras, tools) with minimal changes to the existing structure.

🔄 What Needs to Change?

To mount a different end-effector, all you need to do is replace the part J8_B.

This part acts as the interface between the robotic arm and the end-effector.

Your custom J8_B should:

- Match the hole pattern and dimensions of the original for seamless integration.

- Include mounting features that match your end-effector's design.

- Maintain mechanical strength and alignment.

📂 Reference Files

To help you design your own J8_B, we provide downloadable CAD files.

These files can be imported into most CAD software and serve as a starting point for customization.

🧠 Design Considerations

When creating your custom J8_B, keep the following in mind:

- Mounting Alignment: Ensure that the center of mass and torque loads are balanced relative to the arm’s axis.

- Cable Management: Add holes, channels, or clips for clean wiring if your end-effector needs power or signals.

- Manufacturability: Keep the design simple enough for 3D printing or CNC machining.

🌐 Share Your Design!

If you create a custom end-effector mount and would like to share it with the community, feel free to share it on our Discord channel!

💬 Need Help?

If you run into issues while designing or mounting your end-effector, join our Discord and post on the #faq channel.